Solutions - Trim Scheduling

Solutions®, the latest enhancement in computerized corrugator trimming, provides Plant Schedulers with the tools necessary to efficiently trim all paper grades. Using a newly developed alternative grade scheduling algorithm, Solutions produces the best, most cost efficient trimming solutions available.

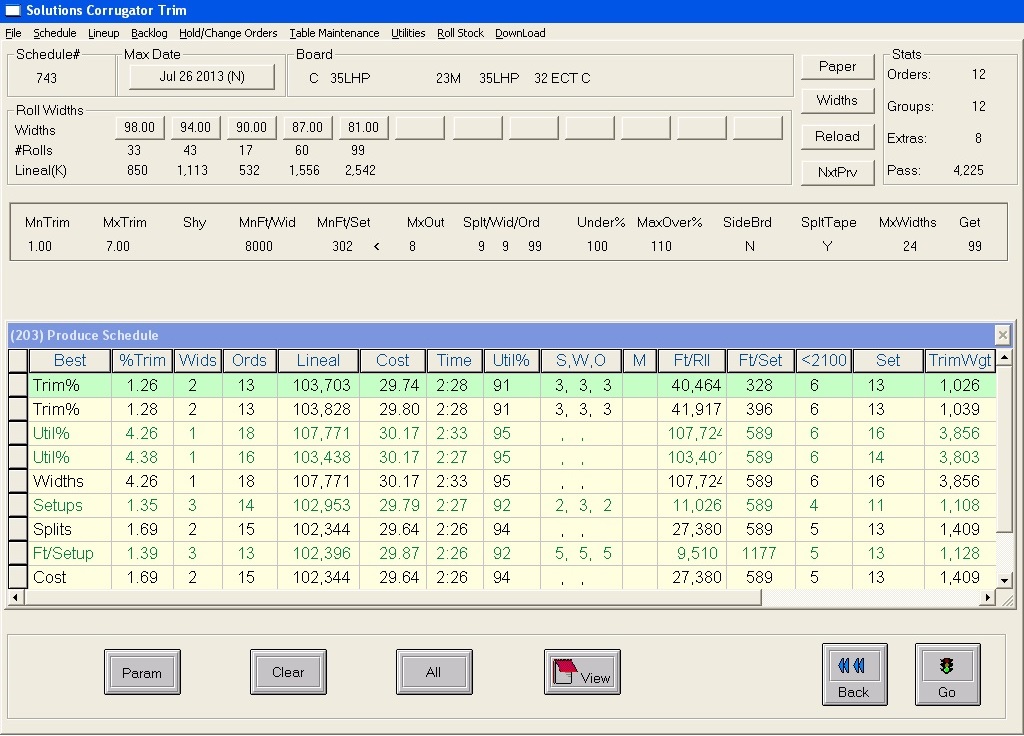

Solutions simultaneously returns multiple trimming solutions based on a series of user defined cost parameters. By examining the results achieved in each solution, the Scheduler can evaluate alternative run patterns and select the specific schedule that best satisfies the Plants current needs - increased corrugator throughput, reduced side trim, reduced order splits, etc.

Solutions will develop better, more cost efficient runs that minimize wet end changes, dry end changes and help control the excess orders being scheduled that lead to material being inventoried, damage to sheets and congestion on the plant floor.

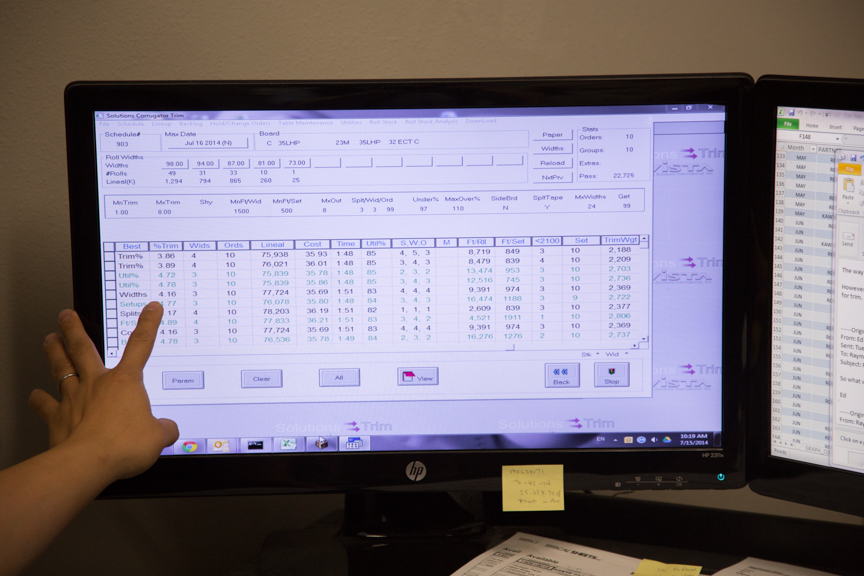

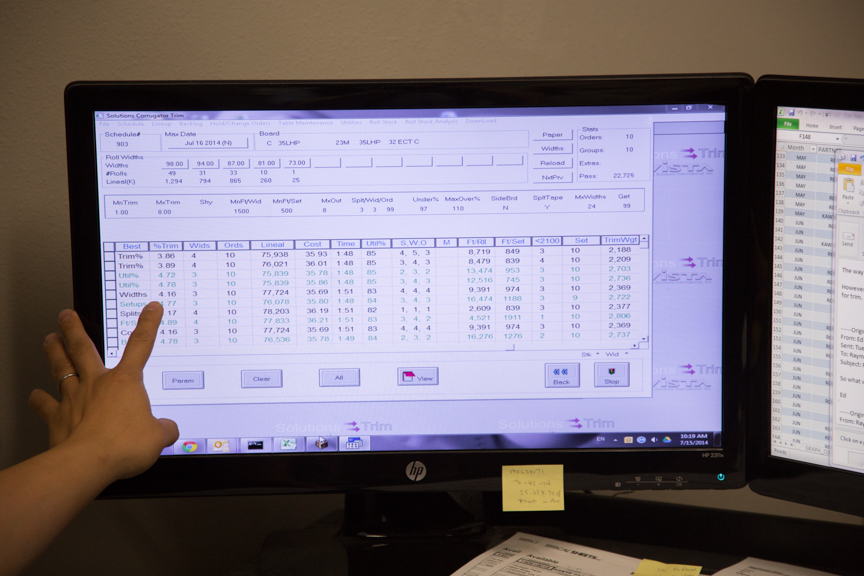

Click to view

Multiple Trims with Cost Calculations

Click to view

Fast and Easy Trims

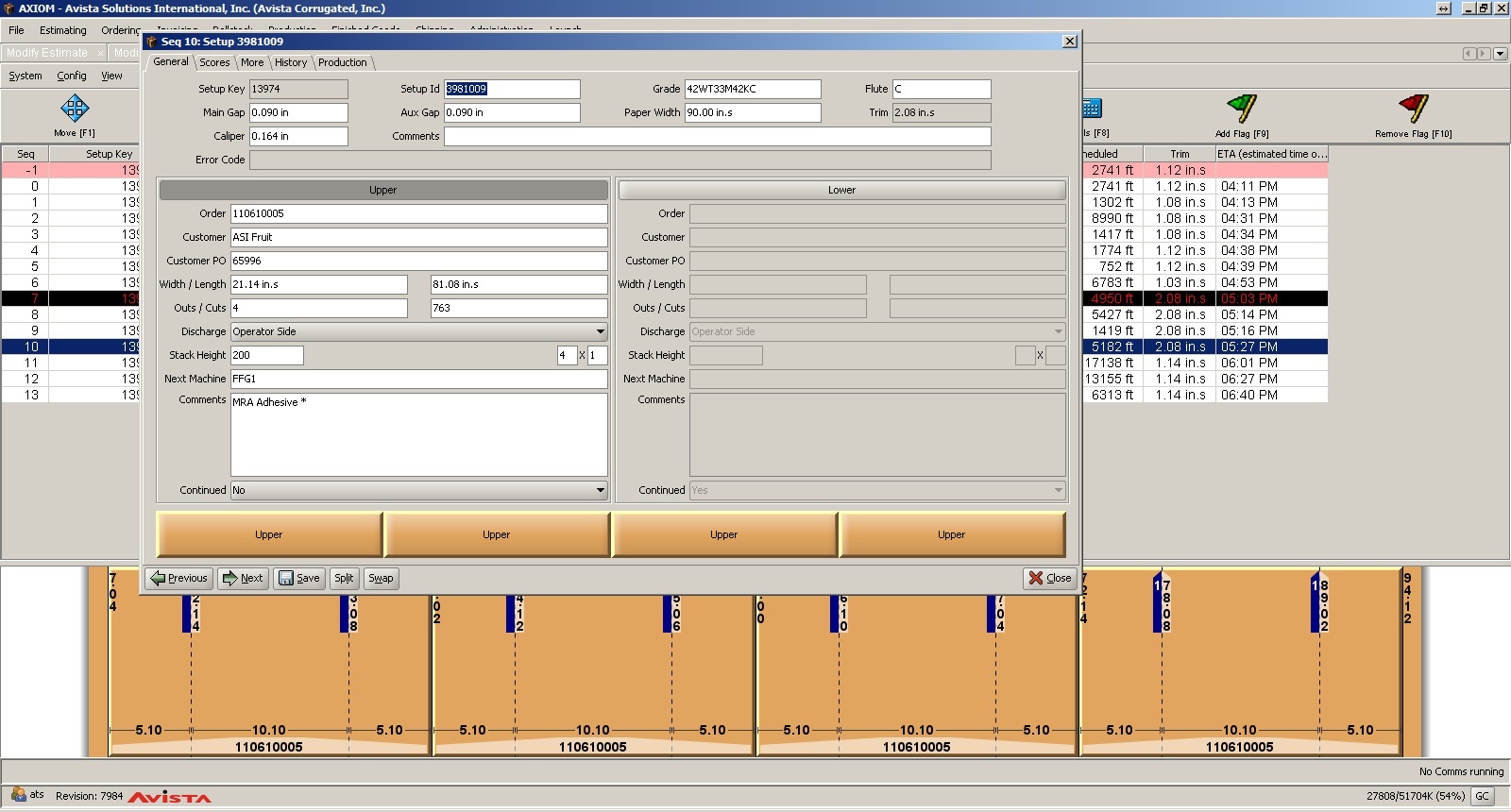

Click to view

Communicate Directly to the Corrugator

Key Benefits of Solutions - Trim Scheduling

- Produces the most efficient corrugator schedules possible fast and easily, allowing the Scheduler to concentrate on improving customer service and plant efficiency instead of number crunching.

- Considers all cost factors and provides decision makers with the best information needed to make the correct decision.

- Produces multiple solutions for each order pool allowing the scheduler to select the one that best fits the current business conditions.

- Solutions trims multiple grades in the same trimming session. Automatically considers upgrades for qualifying orders to create the most cost effective lineups.

- Provides special instructions which are visible through the entire scheduling and corrugating process. This reduces errors and improves communications.

- Provides a wide variety of useful reports aiding management, production and shipping in optimizing their processes.

- Automates communications of the corrugator schedule information to all equipment using Avista Setup Manager®.

Multigrade Scheduling

Solutions automatically trims multiple grades in the same trimming session. Once qualifying orders are selected, lineups are generated using rollstock available at that time.

Alternate Trimming Grades

Solutions automatically considers upgrading orders with the goal of creating more cost effective lineups. The application weighs the decision to upgrade to a heavier board combination only when business rules permit and a cost savings exists. By configuring the board grades, we can specify the allowed upgrade path options for each grade that will be used in the Solutions scheduling strategy. For example, if you had 3 or 4 board grades that were within the same etc range, the scheduler may select all the grades at once. This will load all the orders in those grades into one screen. Upon selecting the required orders, Solutions will combine (keeping in mind the orders upgrade attribute) the orders in the most run/cost efficient manner.

If upgrading an order will improve the overall side trim loss, increase web utilization or reduce wet-end paper changes, Solutions will return that result set in the “Best Cost” solution displayed on the screen. If Solutions determines that the best cost efficient method is to schedule each in its own grade, it will do so. The approach helps improve corrugator through-put, thus providing cost savings.

Cost Calculations

Cost Calculations

Cost Calculations

Solutions includes a new method for calculating the cost of a schedule. Plants can use the original Opportunity Loss Cost calculation method, or a new Straight Cost Calculation method. This new method enables the plant to set costs for the following:

- Cost per Wet-end Paper Change Solutions® Trim System

- Cost per Slitter Change

- Cost per msf above the original msf for orders selected to schedule

- Cost per 100 feet for paper changes before a specified amount of lineal

- Cost per Percent Utilization below desired Target Utilization

- Cost of Upgrades

Auto-parameter Switch

Solutions contains an Auto-Parameter switch which can automatically change the system parameters to allow Solutions to solve difficult scheduling problems. This will make the novice or even the more experienced scheduler’s task easier by allowing Solutions to calculate the minimum requirements for obtaining a successful schedule of selected orders.

Auto Scheduling

Solutions offers an Auto-Scheduling feature which can run in Semi-Auto or Fully-Auto mode. The Semi-Auto mode allows the scheduler to identify required orders for trimming. Once these orders have been marked, one click of a button sets the Auto-Scheduling function into execution. Using plant specified auto-scheduling parameters, Solutions goes through each board grade or grades (if the “Upgrade Path” method is enabled) to create a schedule and a completed corrugator line-up with accompanying reports.

Fully-Auto mode works in conjunction with the Avista Converting Plant Scheduling engine. Solutions takes on more of a scheduling engineroll, scheduling orders that have been identified by the Converting engine to be scheduled. It will continuously loop, looking for orders that require scheduling.

Multi-plant & Multi-corrugator Scheduling

Solutions incorporates improved capability for Multi-Plant scheduling. This method allows for the scheduling of Multiple Corrugators per plant as well. With Solutions set to run in this mode, it can restrict scheduling views to display only orders for each specific plant and or corrugator. It can also be set to include in its display, orders generic to all plants. By assigning Plant Id and Alternate Plant Id to orders, Solutions is able to control scheduling by using the appropriate scheduling parameters for that plant’s corrugator and roll stock supply.

Still have questions? Need more information? We should talk.

Hi, my name is Mark Gartrell with Amtech Automation and we would love to hear from you! If you're considering building a new plant, looking to improve your processes, or need to upgrade to a better solution, I hope you'll give us a call at +1 952.949.0594 to set up a time where we can connect in person or by phone, or email me directly at mgartrell@avistasoftware.com.

For information about how to contact our other employees, please visit our Contact Us page.

Corrugator Management Solutions

Setup Manager

This innovative application provides configurable plant-wide views of your corrugator operation and synchronizes...

Read MoreRoll Inventory Management

This automated application anticipates the arrival of roll stock through an EDI interface. Paper becomes available for consumption...

Read MoreTag Manager

This computer software application is designed to accurately determine the number of sheets in each stacker discharge...

Read More