Tag Manager

The Avista Tag Manager is a computer software application designed to accurately determine the number of sheets in each stacker discharge, print load tags and provide Stacker Operators with order specific information for quality checks. The system automatically creates tags as the loads are actually being built.

The Tag Manager can also create load tags in batch mode for those who do not wish to generate on-the-fly load tags. The Tag Manager supports multiple load tag formats to meet Plant and Customer requirements. Information can be presented in any combination of alphanumeric, embedded graphics and bar code formats.

Click to view

Accurate Sheet Counts for Loads

Click to view

Detailed Inventory Information

Click to view

Provides Information Everywhere

Key Benefits of Tag Manager

- Supports an unlimited number of load tag formats to meet Plant and Customer requirements. Information can be provided in any combination of alphanumeric, embedded graphics and bar code formats.

- Provides an independent count of production cuts and prints the actual number of sheets included in each load.

- Completely eliminates the need to preprint load tags, deploy them to the corrugator and store them until needed. Eliminates the possibility that a unit will be marked incorrectly.

- When required, supports the retagging of loads and the correction of that unit’s count. Easily reproduces tags to replace damaged tags.

- Provides an accurate control record for downstream machines and shipping. Eliminates the opportunity to miss loads which forces additional set ups and additional shipping costs.

- Supports easy interfacing with any other external system while providing a direct link to Avista’s Setup Manager&Reg; and Axiom allowing load generation information to be attached to the individual order record.

- Professionally formatted load tags improve the appearance of outgoing loads and enhance the Plant’s reputation for quality and service.

System Overview

Avista monitoring equipment is installed at the corrugator to verify cut counts and stacker discharges. A LaserJet printer is located at each stacker, an Avista Tag Manager Station is installed near the Bander, and an Avista Workstation is located in the Shipping Department. All stations are connected to an Avista Plant Network.

Prior to the first stack discharge for a new order, the System generates a printout at each stacker detailing the new order number, customer name and load building pattern. The tag is configurable to specific needs and generally contains order information used by the Stacker Operator for quality checks. An order summary sheet can be printed at the end of each order containing a list of all units produced for the partial as well as the counts, number of stacks and customer information for each load. This results in an accurate unit inventory for each unit produced or scrapped. Using data obtained from the monitoring equipment, the Tag Manager determines the actual number of sheets produced for each stacker discharge. It also assigns a unique control number to each completed unit and prints the load tag(s) with all required information, the actual sheet count and control number.

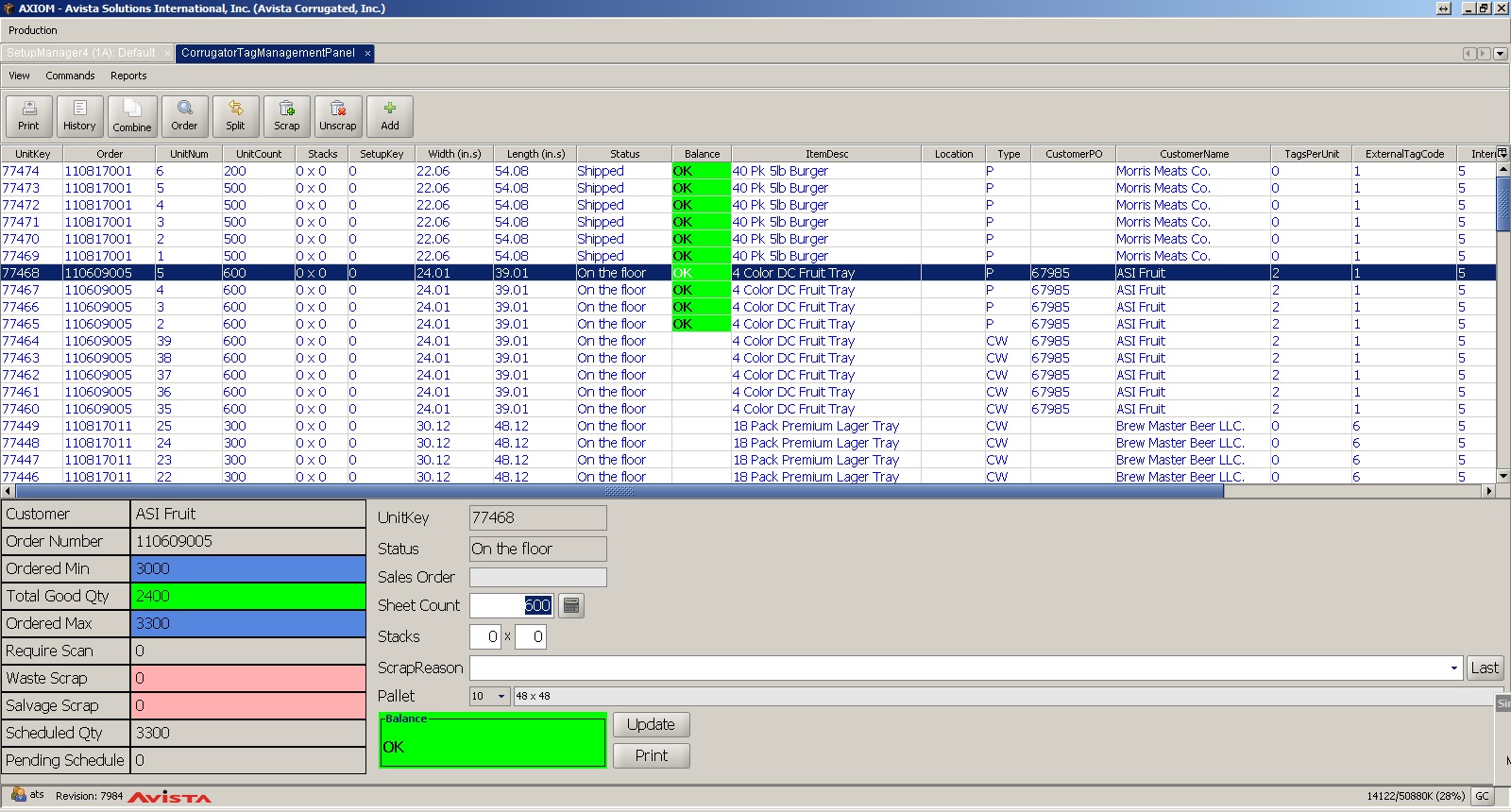

The Bander Operator views the individual units and load tags as they approach his work area. If he needs to correct, replace or generate a tag before banding the unit, he uses the Tag Manager software to produce the new tag on a printer located at his workstation. Using the System, the Operator simply selects a unit in the unit list and uses the Tag Manager’s edit features to make the necessary modifications. Once the modifications are complete, a new tag is automatically printed.

System Configurations

System configurations allow operators to specify if they wish to automatically print incoming tags, automatically print tags after edit and print Start of Order and End of Order summary tags. A Load Building Configuration Table maintains the smart load building parameters used to determine the stacking pattern for each unit produced. A Tag Configuration Table maintains information on all of the tags currently configured for the system.

Unit Manipulation

The Tag Manager allows an operator to edit tags in the unit list or load previously created units back into the system for re-printing of load tags, creating batches or for unit manipulation. The Tag Manager maintains a fixed number of old unit information in the queue for quick access to re-print or edit load tags before it automatically begins to remove older data. New units can easily be added to an order and created in the database using the Load Units feature. Once the unit(s) are loaded, an operator can then print tags for the unit, join one or more units together, split a created unit into smaller units, change unit counts, scrap units, and view history information on the status of the unit. Any and all unit manipulation is recorded and displayed in the unit history window.

Still have questions? Need more information? We should talk.

Hi, my name is Mark Gartrell with Amtech Automation and we would love to hear from you! If you're considering building a new plant, looking to improve your processes, or need to upgrade to a better solution, I hope you'll give us a call at +1 952.949.0594 to set up a time where we can connect in person or by phone, or email me directly at mgartrell@avistasoftware.com.

For information about how to contact our other employees, please visit our Contact Us page.

Corrugator Management Solutions

Solutions - Trim Scheduling

Avista’s advanced, computerized corrugator trimming system automatically delivers an intelligent ranking of multiple...

Read MoreSetup Manager

This innovative application provides configurable plant-wide views of your corrugator operation and synchronizes...

Read MoreRoll Inventory Management

This automated application anticipates the arrival of roll stock through an EDI interface. Paper becomes available for consumption...

Read More